Advantages of the eddy current technique for thickness measurement

Advantages of the eddy current technique for thickness measurement

Advantages of the eddy current technique for thickness measurement

Advantages of the eddy current technique for thickness measurement

Sciensoria’s eddy current thickness measurement technique has many advantages:

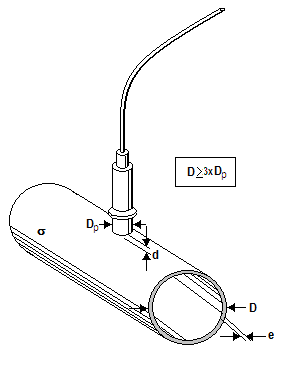

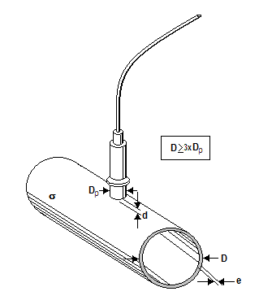

- Single-sided measurement, no mechanical or electrical contact required, capable of measuring on moving targets

- Good tolerance to air gap variation, or tilting of the probe

- Good tolerance to changes in target material: automatic compensation of electrical conductivity, magnetic permeability (only for weakly magnetic materials).

- Small measurement spot allowing good spatial resolution

- Wide measuring range

- Capable of measuring the absolute value of the wall of tubes, tanks and other closed products of materials not previously characterized

The eddy current solution developped by Sciensoria is particularly suitable for inspection of tubes used in airspace technologies since these tubes are made of noble metals (not carbon steel) and have thin wall.

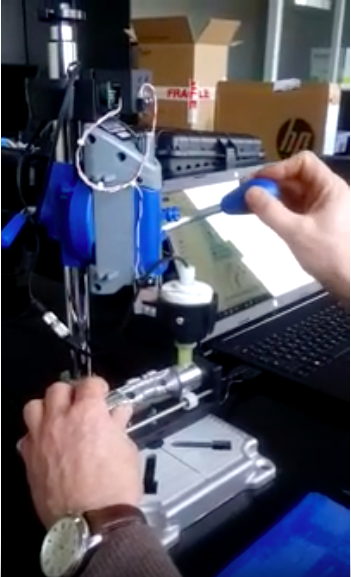

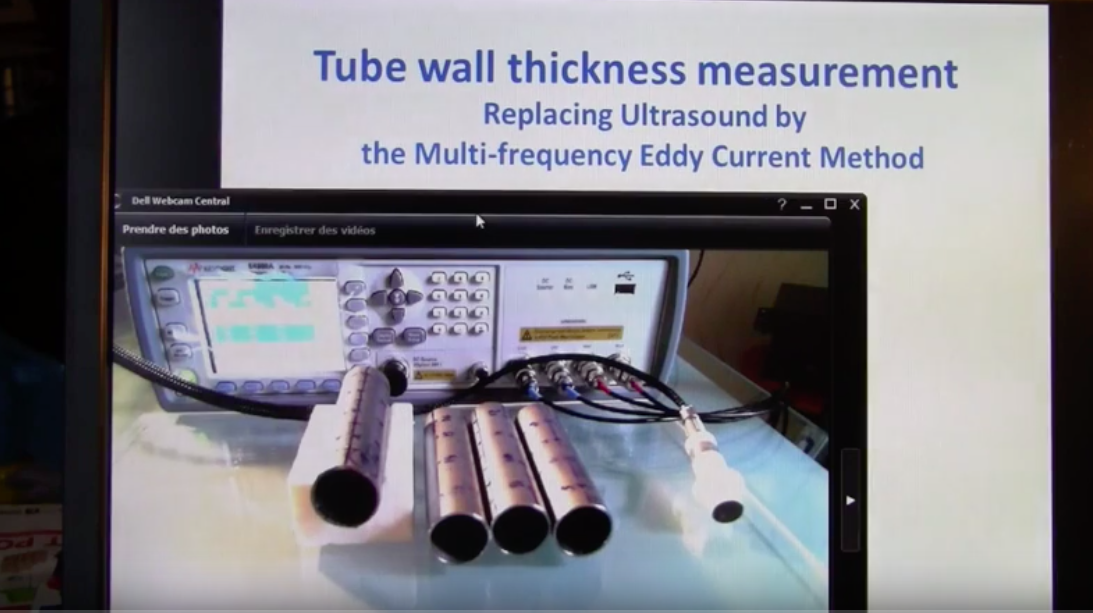

Below is a video clip showing how easy it is to measure tube thickness with the eddy current technique. Click on this link to watch the video: https://youtu.be/Iv8TCL5uVvY.

Sciensoria offers a unique technique that allows simultaneous measurement of both the thickness of curved walls—such as those of tubes, housings, or turbine blades—and the electrical conductivity of the wall material, even under varying lift-off conditions. Unlike ultrasonic methods, the eddy current technique does not require any coupling liquid between the probe and the surface being measured.

Eliminating the need for a couplant is a major advantage when operating in hazardous environments such as nuclear or chemical facilities, as it removes the need for post-measurement surface cleaning.

In 2019, the leading German automotive supplier Mahle ordered two aluminum wall thickness measurement systems from Sciensoria. These systems measure the thickness of aluminum pistons at the production outlet with an accuracy of 0.05 mm over a nominal thickness of 1.5 mm, performing up to 10 measurements per second. To date, more than one million parts have been inspected using Sciensoria’s Conducsens™ systems.

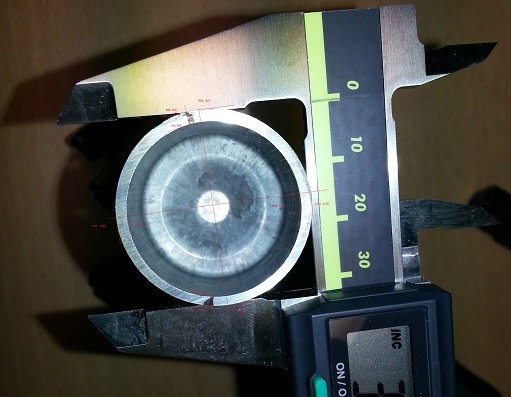

A pair of pistons before grinding

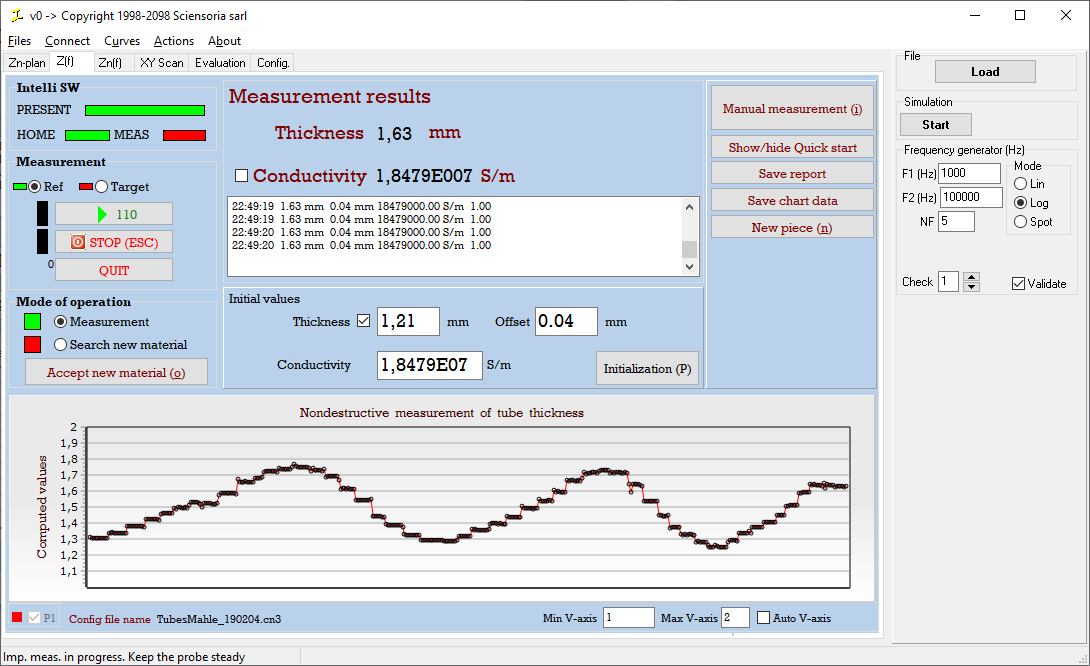

The eddy current nondestructive system Conducsens(tm) which can perform 10 measurements per second

The sectional view of a piston and … (see below)

… evolution of the thickness reading on several turns of the piston

As shown above, the system uses a multi-frequency eddy current method to simultaneously determine both the electrical conductivity of the material (aluminum) and its thickness. Without measuring the material’s electrical conductivity, such accurate thickness measurements would not be possible. This is because electrical conductivity can vary, even within components made from the same grade of aluminum. It can also be affected by ambient temperature. For this reason, continuous monitoring of electrical conductivity is essential during thickness measurement.

The technique is compatible with all metal tubes, including those made of nickel, with the exception of carbon steel tubes.

Further reading:

-

Eddy Current Measurement of Thickness, Electrical Conductivity, and Distance with the Conducsens™ Nondestructive Evaluation (NDE) System — Learn more about Sciensoria’s eddy current technology and the Conducsens™ system.

-

Use of a High-Resolution Probe for Detection of Flaws on Heat Exchanger Tubes — Discover how to detect circumferential (transverse) flaws in tube walls.