Sciensoria is specialist in Non Destructive Testing by electromagnetic methods. We provide solutions for material property measurement, thickness measurement, flaw detection. Our original speciality is eddy current testing, but we have extended our tool range to many other electromagnetic principles and we can intervene in a very broad range of applications in research and industry.

Use our exclusive technologies to control the quality of your materials and products: thickness, electrical conductivity, magnetic permeability, presence of defects, ..., even on the most difficult forms!

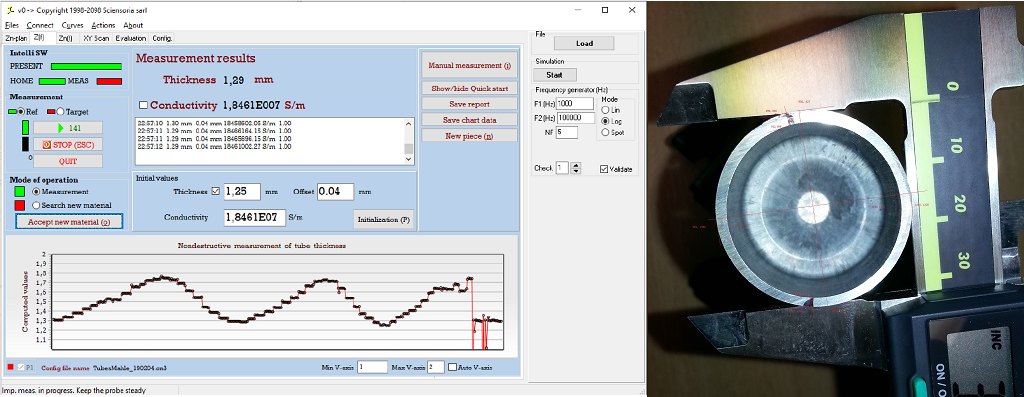

Measurement of thickness

Thickness of products or structures made of conductive materials such as aluminum, copper, titanium, stainless steel, graphite, carbon-fiber composite, … can be measured. The measurement can be carried out from the outside of the surface to be measured, thus allowing a nondestructive evaluation/measurement.

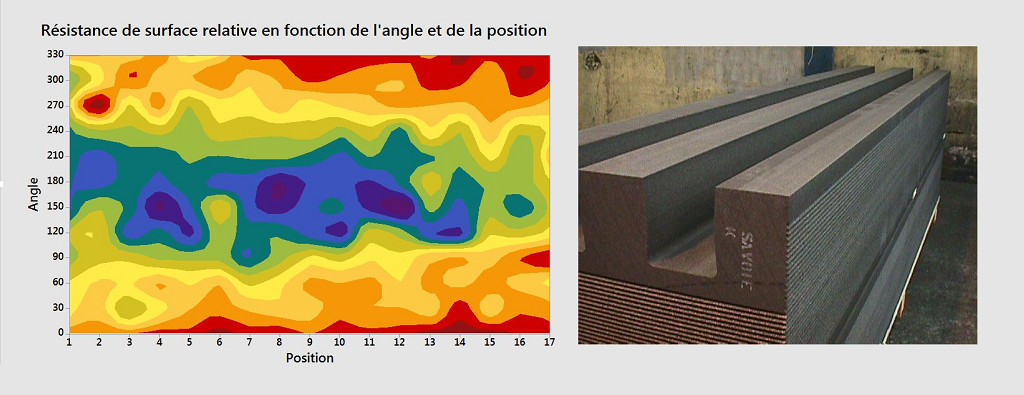

Measurement of electrical conductivity

Measurement is possible on all nonmagnetic metals, some soft steels (magnetic), stainless steels, graphite, carbon-fiber based composite (CFRP). The technology makes it possible to determine electrical conductivity on thin plates or deposits layers.

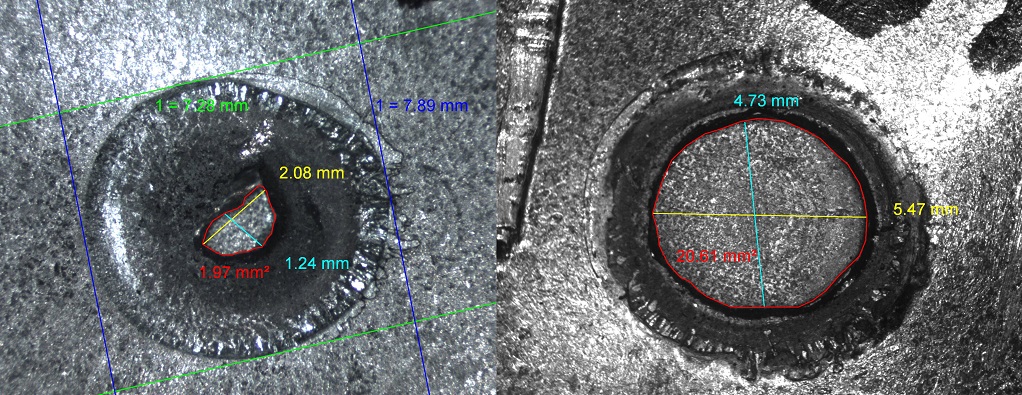

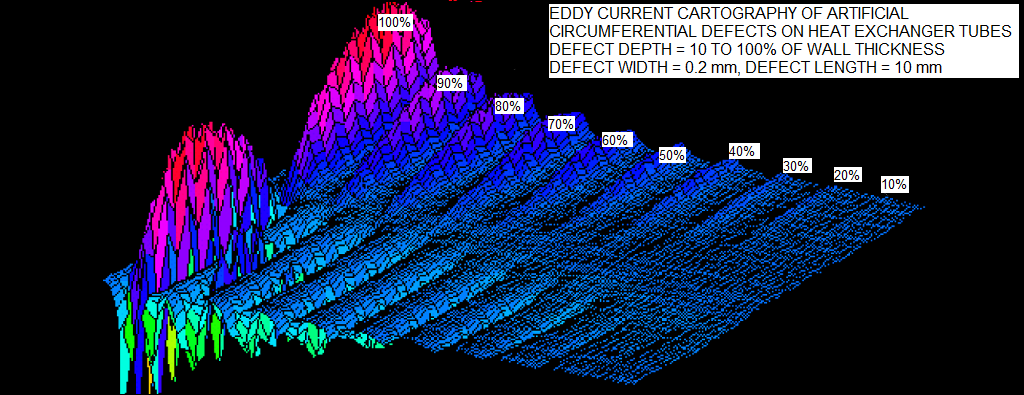

Detection of manufacturing flaws

The measurement of thickness and electrical conductivity of products or structures gives access to their quality assesment. Sciensoria’s technology has been utilised successfully to measure hundred of thousands of car air-conditionner compressor pistons in factory, or to determine the presence of water inside the sheath of submarine oil/gas pipeline.